Subscribe to our Blog

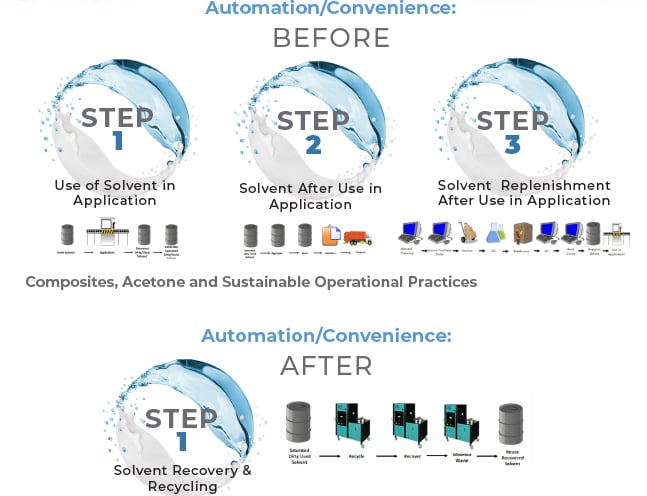

When working with composites, the development of sustainable operational practices is becoming increasingly important. The need to develop sustainable operational practices has become more significant, in part due to supply chain challenges, increasing labor costs and decreasing labor availability.

After forming c omposites, clean up and maintenance is often required. This can be a time consuming process; one which absent of attention can be costly and dent productivity.

omposites, clean up and maintenance is often required. This can be a time consuming process; one which absent of attention can be costly and dent productivity.

To enhance operational effectiveness, composite manufacturers need to challenge assumptions and traditional methods. One strong opportunity for composite manufacturers to develop a sustainable operational practice is to adopt a production solvent recycling solution. This capability enables a composite manufacturer to “Become Your Own Solvent Supplier™.”

A solvent recycling and recovery solution will positively impact:

Sustainability: Significantly less waste is generated and your Acetone is recovered. Generally, residual waste is not incinerated, thereby reducing emissions and providing for generally cleaner air. This also positively impacts your generator status rating with the US Environmental Protection Agency.

Safety: Fundamentally, your facility will physically move your Acetone (solvents) less creating safe work practices; your production recycler can be set up to support your work centers.

Economics: When you adopt a production recycling solution, you will typically recover up to >95% of available solvent with high-concentration levels. This means a savings of up to 90% on purchase and disposal costs. These recovered resources go directly to your bottom line. Production recycling and recovery is an important element for composite manufacturers to develop sustainable operational practices.

Learn More

At CBG Biotech, we rely on a set of customer-first core values that promote ethical and honest behavior, personal accountability, and teamwork to deliver the solutions that set customers up for success. If you have a question or would like more info, please call 800-941-9484 (and press option 3 for support) or get in touch with us online today!

Check out these other helpful resources:

- Blog Post: Use of Acetone in Composite Cleaning

Acetone is frequently used to clean, degrease, strip lacquers, waxes, resins and paints, and is commonly used in varied industrial applications. - Case Study: Columbia University Uses Solvent Recycler to Recycle Acetone, Xylene and Ethanol in Labs

CBG partnered with the Departments of Pathology and Dermatopathology at CUMC to begin an on-site recycling program for spent xylene and ethanol used in these laboratories and returning to it use over and over again. - Video: PathTrue™ Solvent Recyclers for Laboratory Applications

CBG’s fractional solvent distillation systems recycle and reuse xylene, alcohol, acetone, xylene substitutes and formalin in histology, pathology, chemistry and research lab applications.

COMMENTS